Uhlobo lwe-ISWH oluvundlile lwephayiphi yepayipi yensimbi engenasici efakazela ukuqhuma

Incazelo Yomkhiqizo

Iphayiphi lepayipi lensimbi engagqwali evundlile ye-lSWH yamukela imodeli ye-hydraulic ethuthukisiwe, eklanywe ngokuvumelana nemingcele yokusebenza ye-S-isiteji esisodwa sephampu ye-centrifugal yokuncela kanye nesakhiwo esiyingqayizivele sepompo eqondile, futhi iklanywe futhi yakhiqizwa ngokuhambisana ngokuqinile ne-iso2858 yamazwe ngamazwe.Ukusebenza kahle okuphezulu, ukonga amandla, okuthembekile, kulula ukukufaka nokusetshenziswa.

I-lSWH iphampu yepayipi yensimbi engenasici evundlile iyona esetshenziswa kakhulu ekukhiqizeni amakhemikhali, ngoba inohlu olubanzi lokusebenza nokusetshenziswa (okuhlanganisa izinga lokugeleza, ikhanda lokucindezela kanye nokuvumelana nezimo ezimaphakathi), umthamo omncane, isakhiwo esilula, ukusebenza okulula nokugeleza okufanayo. ., ukwehluleka okuncane, ukuphila isikhathi eside, izindleko zokuthenga eziphansi nezindleko zokusebenza kuyizinzuzo ezivelele.

Amapharamitha wokusebenza

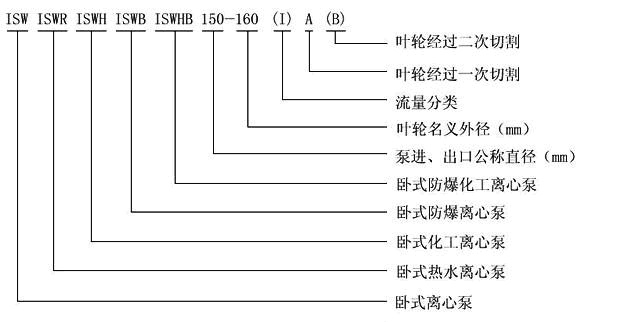

ISWH evundlile efakazela ukuqhuma kwepayipi lensimbi engagqwali incazelo yemodeli yepompo emaphakathi

Izici eziyinhloko ze-ISWH evundlile yepayipi yepayipi yensimbi engagqwali engaqhumi

Ukusebenza okushelelayo: ukugxila ngokuphelele kwe-pump shaft kanye nebhalansi eguquguqukayo nemile ye-impeller kuqinisekisa ukusebenza kahle ngaphandle kokudlidliza.

Akukho ukuvuza kwamanzi: Izigxivizo ze-Carbide zezinto ezihlukene ziqinisekisa ukuthi akukho ukuvuza lapho kuhanjiswa imidiya ehlukene

Umsindo ophansi: Iphampu yamanzi esekelwe amabhereri amabili omsindo omncane ihamba kahle, ngaphandle komsindo omncane wenjini, empeleni awukho umsindo.

Izinga lokuhluleka eliphansi: Isakhiwo silula futhi sinengqondo, futhi izingxenye ezibalulekile zihambisana nekhwalithi yezinga lokuqala lamazwe ngamazwe, futhi isikhathi sokusebenza esingenazinkinga somshini wonke sithuthukiswa kakhulu.

Ukugcinwa okulula: ukushintshwa kwezimpawu, ama-bearings, kulula futhi kulula.

Indawo yaphansi iyonga kakhulu: indawo yokuphuma ingashiywa, kwesokudla nangaphezulu, elungele ukuhlelwa nokufakwa kwamapayipi, ukonga isikhala.

Ububanzi bokusetshenziswa kwephampu ye-ISWH evundlile efakazela ukuqhuma

Iphampu yamanzi ahlanzekile evundlile ye-ISW isetshenziselwa ukuthumela amanzi ahlanzekile nolunye uketshezi olunezici ezifanayo zomzimba namakhemikhali emanzini.Ukushisa, ukufudumeza, ukungena komoya kanye nomjikelezo wesiqandisi, indawo yokugezela nokunye ukucindezela komjikelezo wamanzi abandayo nafudumele kanye nokuhambisana nemishini, izinga lokushisa lokusebenza t≤80°C.

Iphayiphi lepayipi lensimbi engagqwali ye-lSWH evundlile, yokudlulisa uketshezi ngaphandle kwezinhlayiya eziqinile, ukugqwala kanye ne-viscosity efana namanzi, ifanele uphethiloli, amakhemikhali, i-metallurgy, amandla kagesi, ukwenza iphepha, ukudla, iminyango yemithi kanye ne-synthetic fiber, izinga lokushisa elisebenzayo lingu-20 °C ~+120°C.

Iphampu yamanzi ashisayo evundlile ye-ISWR isetshenziswa kabanzi ku: insimbi, imboni yamakhemikhali, indwangu, ukwenza amaphepha, namahhotela nezindawo zokudlela, njengamapayipi amanzi ashisayo ashisayo acindezelwe kanye nezinhlelo zokufudumeza zasemadolobheni, uhlobo lwe-isw olusebenzisa izinga lokushisa elingu-t≤120 ° C I-IsWH yamakhemikhali epayipi lensimbi engagqwali. futha, Ilungele i-petroleum, imboni yamakhemikhali, i-metallurgy, amandla kagesi, i-papermaking, ukudla, imikhakha yemithi kanye ne-synthetic fiber.Izinga lokushisa lokusebenza ngu-20C~+120° C.

Iphampu kawoyela yephayiphi evundlile ye-ISWB isetshenziselwa ukulethwa kwesiza kukaphethiloli, uphalafini, uwoyela udizili neminye imikhiqizo kawoyela noma uketshezi oluvuthayo noluqhuma.Izinga lokushisa eliphakathi nendawo liyi-20~+120°C.

Ukulungiselela ngaphambi kokuqala

1. Hlola ukuthi ukujikeleza kwemoto kulungile yini.Izungezisa ngokwewashi ukusuka phezulu kwenjini ukuya empompini.Isikhathi sokuhlola kufanele sibe sifushane ukugwema ukuguga okomile kwesigxivizo somshini.

2. Vula i-valve yokukhipha umoya ukuze ugcwalise wonke umzimba wepompo ngoketshezi, futhi uvale i-valve yokukhipha umoya lapho isigcwele.

3. Hlola ukuthi zonke izingxenye zijwayelekile yini.

4. Shayela iphampu mathupha ukuze wenze uketshezi lokugcoba lungene ekugcineni kwesigxivizo somshini.

5. Uhlobo lokushisa eliphezulu kufanele lushiswe kuqala, futhi izinga lokushisa kufanele lenyuke ngo-50℃/ihora ukuze kuqinisekiswe ukuthi zonke izingxenye zishisisa ngokulinganayo.

Qala

1. Vula ngokugcwele i-valve yokungena.

2. Vala i-valve yepayipi lokukhipha.

3. Qala injini bese ubheka ukuthi iphampu isebenza kahle yini.

4. Lungisa ukuvulwa kwe-valve yokuphuma ukuze kuhlangatshezwane nezimo zokusebenza ezidingekayo.Uma umsebenzisi efakwe imitha yokugeleza noma igeji yokucindezela endaweni yepompo, iphampu kufanele isebenze endaweni elinganiselwe esohlwini lwethebula lepharamitha yokusebenza ngokulungisa ukuvuleka kwevalvu yokuphuma.Umsebenzisi ufakwe imitha yokugeleza noma igeji yokucindezela ekuphumeni kwepompo, futhi kufanele alungise ukuvuleka komnyango wokuphuma ukuze kulinganiswe amandla amanje enjini epompo, ukuze injini isebenze ngaphakathi kwamandla amanje alinganiselwe, ngaphandle kwalokho iphampu izokwenza. kulayishwe kakhulu (okungukuthi, ukusebenza kwamanje okuphezulu).ukushisa injini.Usayizi wokuvula we-valve yokuphuma elungiswe kahle uhlobene nezimo zokusebenza zepayipi.

5. Hlola ukuvuza kwe-shaft seal.Imvamisa, ukuvuza kophawu lwemishini kufanele kube ngaphansi kwamaconsi ama-3/min.

Hlola ukuthi izinga lokushisa liyakhuphuka yini kumotho kanye nokuthwala kungu-≤70°C.

Ukupaka

1. Ngohlobo lokushisa oluphezulu, pholisa kuqala, pholisa bese upheka u-<10°C, futhi wehlise izinga lokushisa libe ngaphansi kuka-80°C ngaphambi kokupaka.

2. Vala i-valve yepayipi lokukhipha

3. Misa injini.

4. Vala i-valve yokungena

5. Uma imisiwe isikhathi eside, uketshezi olusepompo kufanele luphele.

Inothi elikhethekile

Iphampu yamanzi engaphansi kuka-7.5kW ingahlonyiswa ngamaphedi okuvezela ahlukanisayo futhi ifakwe ngqo esisekelweni.

Uma ingaphezu kuka-7.5kw, ingafakwa ngokuqondile nesisekelo sokuphonsa, noma ingafakwa ne-isolator yenkampani yethu.Indlela yokufaka yesihlukanisi iyafana nosayizi wesihlukanisi esimataniswa nepompo ye-ISG.Izihlukanisi zamaphampu zinosayizi ofanayo