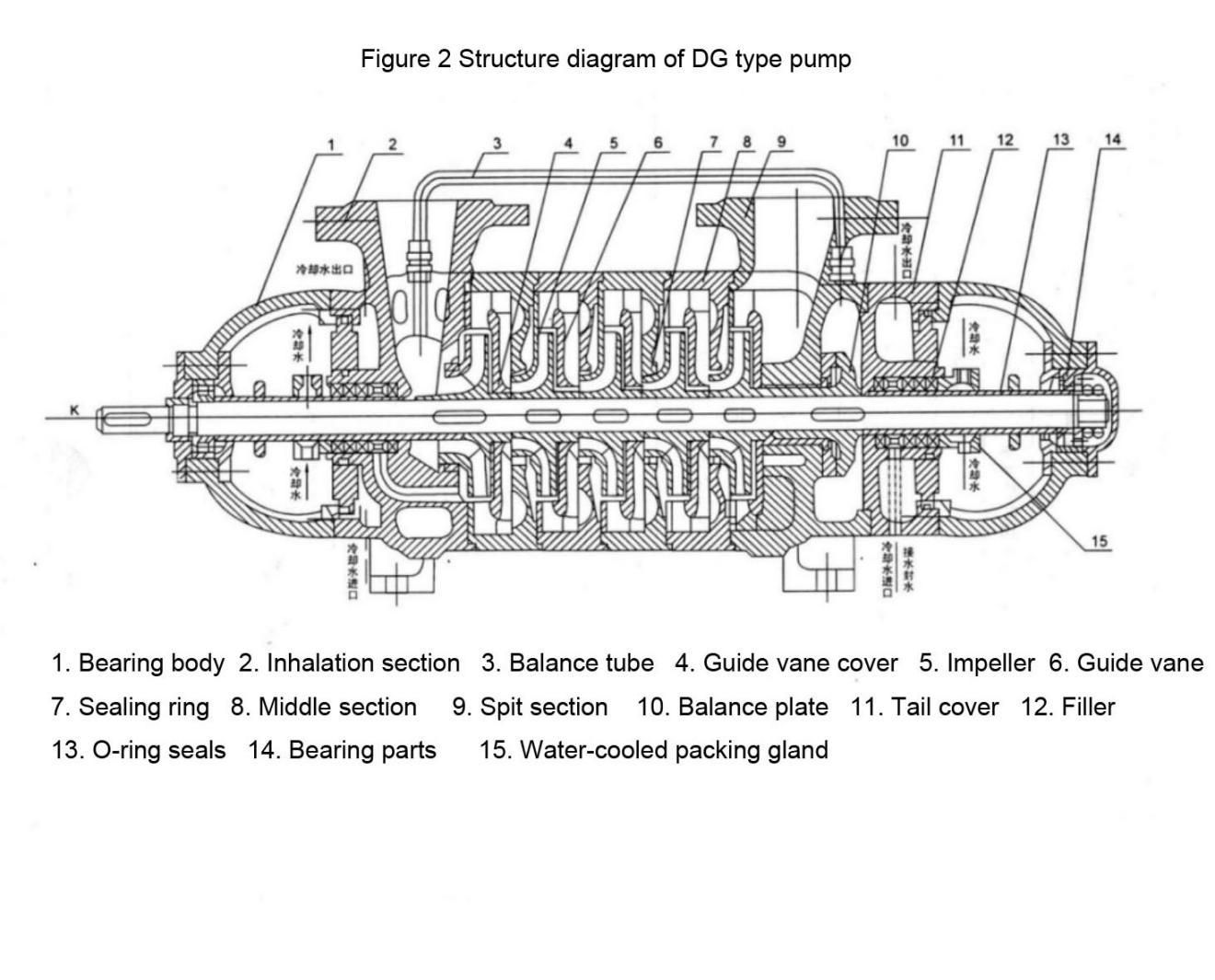

Iphampu yokuphakelayo ye-boiler enezigaba eziningi ye-DG

1. Sebenzisa

1.1 Amaphampu e-D kanye ne-DC angamaphampu aphakathi kwezigaba eziningi.Ilungele ukuthuthwa kwamanzi (okuhlanganisa nengxubevange yesisindo esingaphansi kuka-1%. Usayizi wezinhlayiyana ungaphansi kuka-0.1 mm) kanye nolunye uketshezi olufana namanzi emanzini.

Izinga lokushisa le-D-type transport medium alikho ngaphezu kuka-80 ° C. Ifanele ukugeleza kwamanzi ezimayini kanye nezimboni, ukuhlinzekwa kwamanzi emadolobheni nezinye izikhathi.

Izinga lokushisa lephampu ye-DG yokudlulisa ingaphakathi alikho ngaphezu kuka-105 ° C. Kufanelekile kuma-boilers amancane ukupompa amaphampu noma ukuthutha amanzi ashisayo afanayo.1.2 Ibanga lokusebenza lalolu chungechunge (ngokwemithethonqubo):...

ukugeleza: 6.3 ~ 450m³/h

ukuphakama: 50 ~ 650M

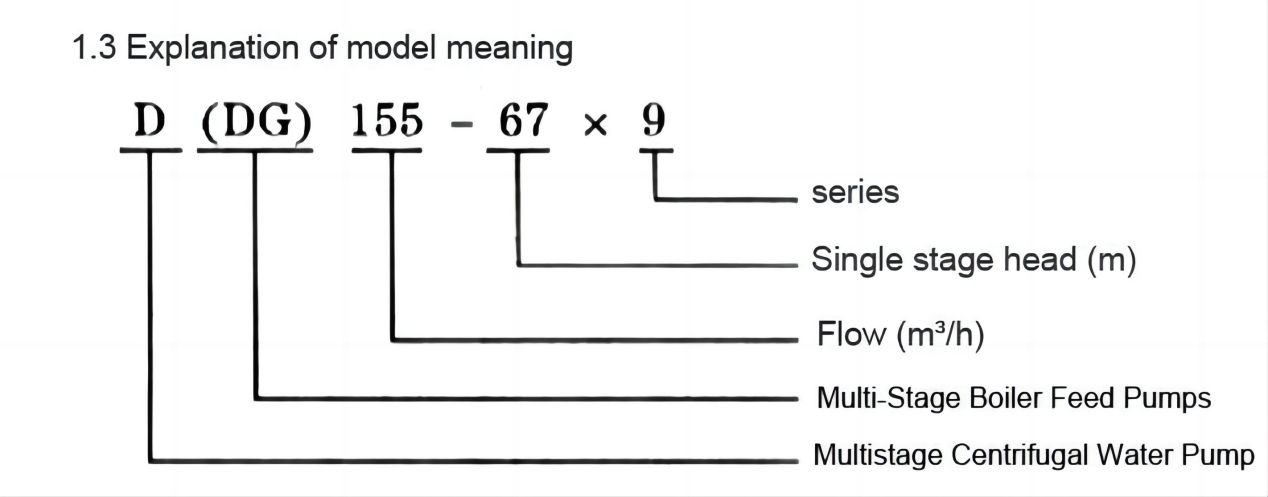

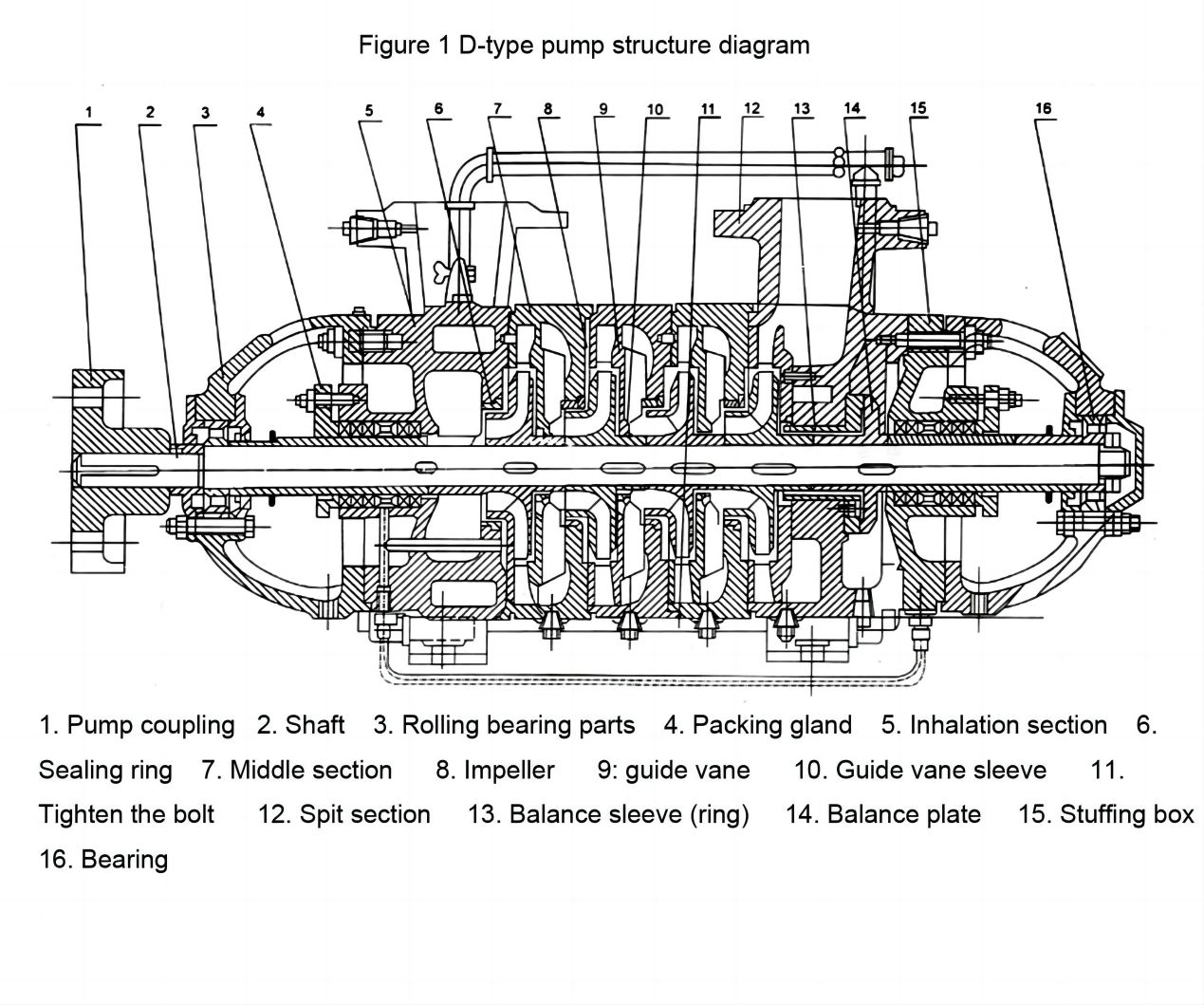

2. Incazelo Yesakhiwo

Lolu hlobo lwepompo ikakhulukazi lwakhiwe ingxenye yegobolondo, ingxenye ye-rotor, indlela yokulinganisa, ingxenye ephethe kanye nezingxenye zokuvala.

1. Ingxenye yegobolondo

Ingxenye yegobolondo ngokuyinhloko yakhiwe ingxenye yokumunca, ingxenye ephakathi, ingxenye yokukhipha, i-vane yomhlahlandlela, umzimba othwalayo, njll. exhunywe ngamabhawudi.Indlela yokuzungezisa iphampu, uma ibukwa kusukela ekugcineni kwedrayivu, iphampu izungeza ngokwewashi.

2. Ingxenye ye-Rotor

Ingxenye ye-rotor ikakhulukazi yakhiwe i-shaft kanye ne-impeller efakwe ku-shaft, umkhono we-shaft, i-balance disc nezinye izingxenye.Izingxenye eziku-shaft ziboshwe ngezihluthulelo eziyisicaba kanye namantongomane e-sleeve ukuze zihlanganiswe ne-shaft, futhi yonke i-rotor isekelwe ku-casing yepompo ngama-bearings kuzo zombili iziphetho.Inombolo yama-impellers emhlanganweni we-rotor isekelwe kwinani lezigaba zepompo.

Lapho lolu hlobo lwepompo lusetshenziswa, uphawu lwe-shaft kufanele luthole amanzi ukuze luvale amanzi.Kunezinhlobo ezimbili zezimpawu zamanzi: enye iwukusebenzisa amanzi aphumayo e-impeller yesiteji sokuqala, kanti enye iwukusebenzisa amanzi angaphandle.Wonke amanzi ophawu oluphawulwe kuThebula 2 abhekisela emanzini ophawu lwamanzi angaphandle, futhi amanzi ophawu lwamanzi esiteji sokuqala asetshenziswa njengamanzi ophawu lwamanzi kulabo abangaphawulwanga ngamanzi ophawu lwamanzi.Ukuqina kokupakishwa kwe-shaft seal kufanele kube ngokufanele, futhi kuyatuseka lapho uketshezi lukwazi ukuphuma ngethonsi.Lapho izinga lokushisa lendawo edluliswayo lingaphezu kuka-80°C, amanzi okupholisa awuketshezi kufanele adluliselwe endlaleni yokupakisha epholiswe ngamanzi kanye negumbi lokupholisa le-shaft seal.3 kg/cubic centimeter, ukucindezela kwamanzi ophawu lwamanzi kungu-0.5-1 kg/cubic centimeter ephakeme kunaleyo yomgodi wokuvala.Ukuma kwesixhumi esibonakalayo sepayipi lophawu lwamanzi kanye negumbi lokupholisa le-shaft seal yamaphampu ahlukahlukene kuhlukile.Ukuma kwesixhumi esibonakalayo sepayipi eduze kwendlela ye-axial kuboniswa kumdwebo wesakhiwo sephampu.

3. Indlela yokulinganisa

Indlela yebhalansi yakhiwe indandatho yebhalansi, umkhono webhalansi, i-balance disc kanye nepayipi lebhalansi, njll.

4. Ukuba nengxenye

Ingxenye ephethe ngokuyinhloko yakhiwe umzimba othwalayo kanye ne-bearing.Lolu hlobo lwe-pump bearings lunezinhlobo ezimbili: ama-sliding bearings nama-flow bearings.Awekho ama-bearings ane-axial force.Lapho ipompo isebenza, ingxenye ye-rotor kufanele ikwazi ukuhamba ngokukhululekile nge-axially ku-casing yepompo.Ama-radial ball bearings awakwazi ukusetshenziswa.Ama-bearings asetshenziswa izinhlobo ezahlukene zamaphampu akhonjisiwe kuThebula 1.

5. Ukuvalwa kwepompo nokupholisa

Indawo ehlangene yesigaba sokumunca, ingxenye ephakathi, ingxenye yokukhipha kanye ne-vane yomhlahlandlela engxenyeni yegobolondo igcotshwe ngamafutha e-molybdenum disulfide ukuze kuvalwe uphawu.

Ingxenye ye-rotor kanye nengxenye engaguquki ivalwa ngokuvala izindandatho, imikhono ye-vane eqondisayo, izigcwalisi, njll. Uma izinga lokuguga kwendandatho yophawu kanye nomkhono we-vane we-guide kuthinte umsebenzi nokusebenza kwepompo, kufanele kushintshwe ngesikhathi. .Uma le modeli isetshenziswa, indawo yendandatho yokupakisha kufanele ibekwe ngendlela efanele.Bheka Ithebula lesi-2 ngokusatshalaliswa kokupakisha nokupakisha izindandatho zezinhlobo ezahlukene zamaphampu.